Chung Yuan Christian University’s industry talent cultivation base, the “Knowledge and Action Leadership Hall,” has reached its five-year milestone. To celebrate, the “Smart Leadership: Five-Year Journey” anniversary event will be held on May 22-23, 2024. Experts, scholars, and industry representatives from various fields will gather to witness the technological advancements of CYCU’s Smart Manufacturing Research Center over the past five years. Industry partners such as Siemens and Otsuka Information Technology donated software and hardware, while Taichung Machinery, THE SYSCOM GROUP and PacketX Technology showcased the outcomes of industry-academia collaborations. Additionally, THE SYSCOM GROUP and PacketX Technology assisted CYCU in establishing the nation’s only 5G Smart Manufacturing Demonstration Production Line, marking a new milestone in CYCU’s smart manufacturing development.

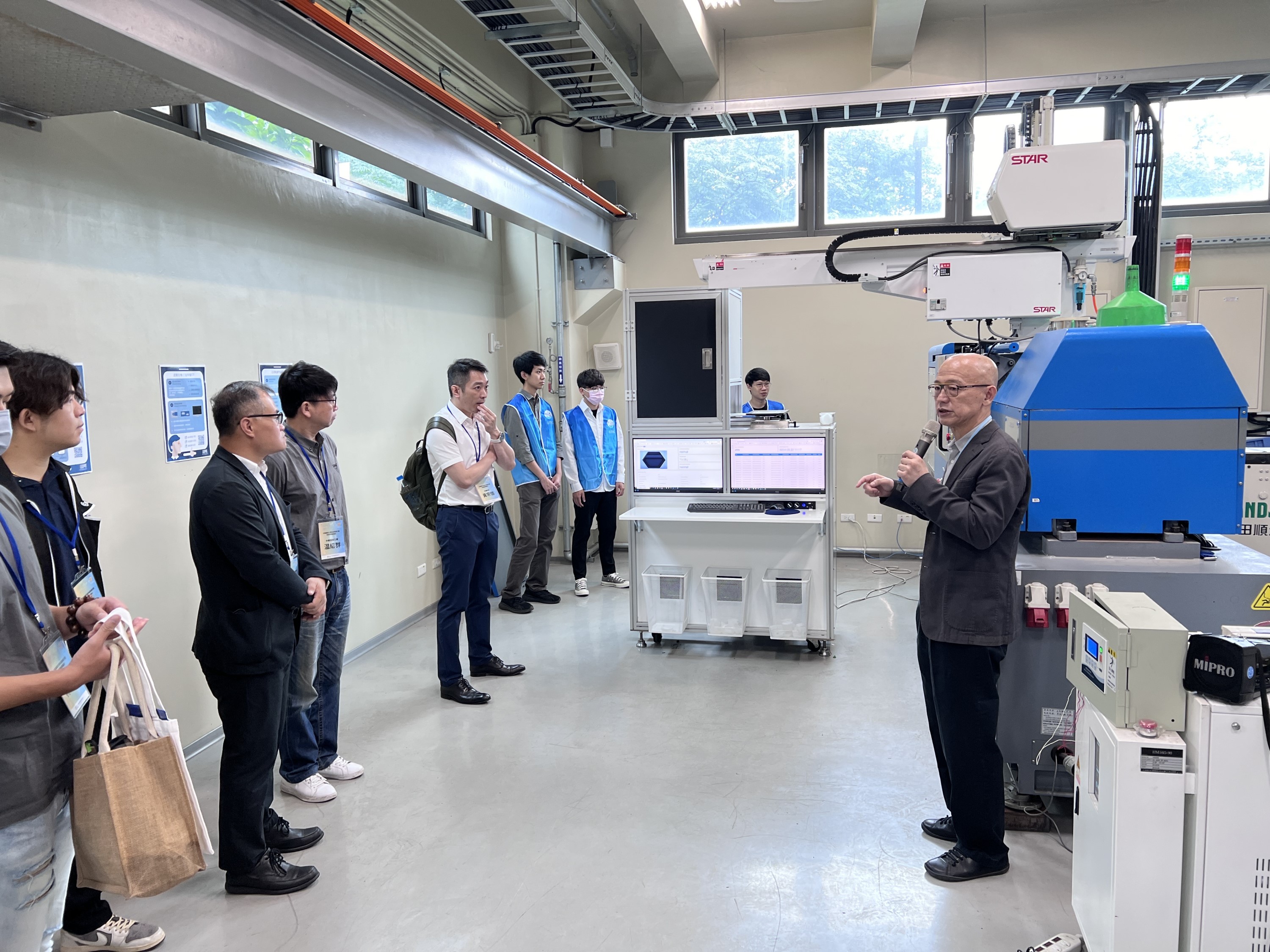

To address the needs of Taiwan’s industry during the Fourth Industrial Revolution, CYCU focused on “Smart Manufacturing” and completed the construction of the three-story, 1,642-ping “Knowledge and Action Leadership Hall” in March 2019. It features the nation’s most comprehensive Industrial 4.0 automation demonstration production line and service area, promoting interdisciplinary technological integration to drive industry-academia innovation and serve as a talent cultivation base. Over the past five years, the Smart Manufacturing Research Center has executed projects worth over NT$120 million, attracting more than 5,000 visitors. The five-year celebration will kick off with a software and hardware donation and a memorandum of understanding signing ceremony on the morning of May 22 at the Knowledge and Action Leadership Hall.

To promote the application and dissemination of smart manufacturing technology, Siemens donated NX Academic-Core&CAD and NX Academic-CAE&CAM software licenses to CYCU for course development and research. Otsuka Information Technology is providing technical support to further advance the use and promotion of smart manufacturing technologies. Additionally, CYCU has signed industry-academia cooperation memorandums with several companies. Taichung Machinery will develop an innovative project for full-electric injection molding machines within the demonstration production line. Meanwhile, THE SYSCOM GROUP and PacketX Technology will collaborate to establish a 5G network, creating the nation’s only smart manufacturing demonstration production line on a university campus.

Chung Yuan Christian University Smart Manufacturing Research Center Director, Chen Xia-Zong, expressed his gratitude to all supporters of CYCU and the Smart Manufacturing Center during his opening speech. He announced that the center will undertake the “Value-Added Project for Intelligent Manufacturing Equipment in the Precision Injection Molding Tooling Industry” funded by the Industrial Development Bureau of the Ministry of Economic Affairs. The project includes the procurement of high-precision equipment such as metal 3D printers and precision five-axis CNC machines, along with relevant digital transformation and intelligent software. The goal is to upgrade multiple software and hardware systems to provide advanced manufacturing technology services for the domestic tooling industry and to assist in the industry’s accelerated upgrade and transformation through close industry-government-academia-research cooperation, enhancing international competitiveness.

General Manager of the Plastics Industry Development Center, Hsiao Yao-Kuei, also commended CYCU’s Smart Manufacturing Research Center for its contributions to the plastic mold industry and looked forward to more collaborative research and development in the future.

On the afternoon of the 22nd, four special lectures took place. The first speaker was Professor Gaofurong from the Hong Kong University of Science and Technology, who presented on “Batch Process Automation: A Thermoplastic Injection Molding Example.” His talk covered high-level data modeling and automated control in batch process automation, focusing on thermoplastic molding, as well as the potential applications of next-generation capacitive sensors. His insights were well received by the attendees.

Following him, Manager Huang Zhi-Jie from Otsuka Information Technology introduced “Advanced Mechanical Engineering Based on Siemens Digital Thread,” showcasing the advantages and potential of the latest digital manufacturing technologies. THE SYSCOM GROUP demonstrated their latest products and technologies in the field of smart manufacturing and shared how 5G private networks can drive intelligent transformation in factories. Professor Zhong Wen-Ren from CYCU’s Department of Mechanical Engineering also shared his professional insights on AI autonomous agents in the injection molding process.

On the second day of the event, May 23rd, the “Green Cybersecurity Workshop” was held. Experts and scholars from National Central University, Chung Yuan Christian University, the Industrial Technology Research Institute, and the Plastics Industry Development Center were invited to discuss the challenges and solutions related to information security and net-zero carbon emissions in the development of the smart manufacturing industry. The two-day event not only fostered exchange and collaboration between industry, academia, and research sectors but also injected new momentum and vitality into the field of smart manufacturing.

自臺大教授謝銘倫(左)手中接任理事長。.jpg)